Beer Keg

A beer keg is a container typically made of metal, commonly stainless steel, designed to store and dispense beer. It's a popular vessel used in bars, breweries, and parties for serving large quantities of beer to customers or guests. Kegs come in various sizes, from smaller ones suitable for home use to larger ones for commercial purposes. The beer inside the keg is pressurized with carbon dioxide or a mixture of nitrogen and carbon dioxide to maintain freshness and proper carbonation levels until it's poured into a glass for consumption.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

What is Beer Keg

A beer keg is a container typically made of metal, commonly stainless steel, designed to store and dispense beer. It's a popular vessel used in bars, breweries, and parties for serving large quantities of beer to customers or guests. Kegs come in various sizes, from smaller ones suitable for home use to larger ones for commercial purposes. The beer inside the keg is pressurized with carbon dioxide or a mixture of nitrogen and carbon dioxide to maintain freshness and proper carbonation levels until it's poured into a glass for consumption.

Advantages of Beer Keg

Less waste

When dealing with bottles, breweries can expect substantial waste and losses. Bottles can break or get damaged during storage and transportation. Retailers often return unsold products with kegs, however, there is minimal waste. Kegs are durable stainless steel that holds up well to handling. They're also reusable - once emptied, the brewery simply takes back the keg, sanitizes it, and refills it.

Lower costs

In addition to the economic advantages of kegs over bottles, their reusability further solidifies their appeal in the beverage industry. Kegs are designed to be durable and easily cleaned, allowing them to be reused multiple times, unlike bottles and cans, which typically have a limited lifespan. This reusability not only reduces the environmental impact associated with single-use packaging but also enhances the overall cost efficiency for both producers and distributors.

Better beer freshness

Oxygen is the enemy of beer freshness. Bottled beer constantly exposes the liquid to oxygen every time a bottle is opened. Kegs, however, allow beer to stay protected from oxygen during storage and pouring, keeping it fresher for longer. The stainless steel construction and single-use nature of kegs provide ideal beer freshness.

Versatility

The versatility of kegs extends beyond their use in traditional brewery settings. Due to their durability and ease of handling, kegs find applications in various venues, such as bars, restaurants, and large events. The streamlined logistics of keg distribution make it a preferred choice for businesses aiming to minimize storage space requirements and transportation costs.

Why Choose US

One-stop solution

With rich experience and one-to-one service,we can help you choose products and answer technical questions.

01

Customization services

They provide customization services to meet specific customer requirements, ensuring that clients receive products that exactly fit their needs.

02

Innovation

We are dedicated to improving our systems continually, ensuring that the technology we offer is always cutting edge.

03

24h online service

We try and respond to all concerns within 24 hours and our teams are always at your disposal in case of any emergencies.

04

What Materials Are Beer Kegs Typically Made From

Beer kegs come in a range of materials, from steel to plastic. They all help protect the beer from outside elements, enabling you to enjoy it at its best taste. Generally speaking, there are three main types of material used for beer kegs: steel, aluminum, and plastic.

Steel Kegs

Steel is the most common material used for beer kegs – sometimes referred to as the "standard" material when referring to beer kegs. It's durable and helps keep your draft beer colder than other materials while also providing an attractive look.

Most important advantages:

- Durability

- Attractive look

- Longer shelf life for draught beers

- Helps maintain cold temperatures better than other materials

Aluminum Kegs

Another commonly used material for beer kegs is aluminum. Aluminum helps preserve the taste and quality of your favorite beers while also being lighter than steel kegs – making them easier to move around or transport if necessary. Aluminum also has excellent contact with cold surfaces so your draft beers will stay cold longer than with other metals!

Most important advantages:

- Lightweight compared to steel or copper kegs

- Excellent contact with cold surfaces for optimal temperature preservation

- Good thermal insulation properties

Copper Kegs

The third metal most commonly used for beer kegs is copper – often referred to as a "luxury" material due to its higher cost compared with other metals such as steel and aluminum. Copper provides excellent insulation properties, keeping your favorite brews at their optimal temperature longer and preserving their flavor profile over time much better than other metals can provide!

Most important advantages:

Excellent insulation properties for optimal flavor preservation over time – Attractive appearance – Good thermal conductivity (if strong enough)

Plastic Kegs

Plastic is also becoming more popular when it comes to manufacturing beer kegs – they provide an effective way of storing draft beers while being lightweight and more economic compared to metal options like aluminum or steel. On top of that, they tend to be more resistant against punctures or dents while still providing good contact with cold surfaces; enabling you to enjoy your brews at their best temperatures!

Most important advantages:

Lightweight construction makes them easy to transport or move around – more economical option compared to metal alternatives – High resistance against punctures or dents – Good contact with cold surfaces helps maintain optimal temperatures.

Components of a Beer Keg

Tap and faucet

The tap and faucet are the most visible components of a keg. They are used to dispense beer from the keg. The tap or beer coupler is attached to the keg valve, while the faucet lever is attached to the tap handle. The valve holds the beer inside the keg while the faucet lever and tap allows it to flow. Keg taps come in different types, including Sankey couplers and keg couplers. The faucet lever is typically made of brass or stainless steel and has a lever that controls the flow of beer.

Beer lines and seals

The beer lines and seals are used to transport beer from the keg to the draft beer faucet. The draft beer faucet line is a tube that connects the draft beer faucet back to the keg. The line is typically made of food-grade plastic or vinyl. The seals are used to prevent leaks and maintain the pressure inside the keg. They are typically made of rubber or silicone and are placed between the various components of the keg.

Spear and dip tube

The spear and dip tube are used to pull and dispense beer from the keg. The spear is a metal tube that is inserted into the keg and is used to pull and inject gas into the keg. The dip tube is a metal tube that extends from the spear to the bottom of the keg. It is used to draw beer from the keg and transport it to the beer line.

A keg consists of several components, including the tap and beer faucet itself, beer lines and seals, spear, and dip tube. Each component plays a crucial role in the whole draft system and beer dispensing process, and it is essential to ensure that they are all in good working condition to avoi

Beer Keg Equipment

Beer keg equipment is essential for the storage, dispensing, and delivery of draft beer. From kegerators to CO2 tanks and regulators, there are many components that go into a good kegging setup for draft system.

Kegerators and draft beer systems

A kegerator is a refrigerator that is specifically designed to hold a keg of beer and dispense it through a two tap system. It is an excellent choice for homebrewers who want to enjoy draft beer without the hassle of filling bottles. A kegerator typically comes with a drip tray, CO2 tank, regulator, and beer lines. It is important to choose a kegerator that is the right size for your keg and has the necessary features for your draft beer dispensing needs.

CO2 tanks and regulators

CO2 tanks, accessories and regulators are essential accessories for carbonating and dispensing beer from a keg. The CO2 tank is filled with compressed gas, which is used to push it out of the keg. The regulator controls the flow and pressure of the gas, which affects the carbonation and dispensing of the beer. It is important to choose a regulator that is compatible with your CO2 tank and has the necessary features for your needs.

Hand pumps and dispensers

Hand pumps and dispensers are an alternative to CO2 tanks and regulators. They use air pressure to dispense beer from a keg, making them ideal for outdoor events or situations where electricity is not available. Hand pumps require manual pumping to dispense the beer, which can be tiring and affect the quality of the beer. Dispensers are a more convenient option that uses a pressurized air tank to dispense the beer.

Beer in Beer Kegs

When it comes to serving beer, kegs are a popular choice among beer bar enthusiasts. They are durable, portable, and can hold a large amount of beer. we will discuss the different types of beer and beverages that can be sold separately stored in kegs, the importance of beer taps and lines in beer bar, and how flavors and quality can be affected.

Types of beer

Kegs can hold a variety of beers, including craft brew beer, other beers, and imported beer. Draft beer is a type of beer that is not pasteurized, and it is typically served cold. It's a beer that is brewed by small, independent breweries, and it often has unique flavors and ingredients. Imported beer is a beer that is brewed in a different country and then imported to the United States.

Beer taps and lines

Beer taps and lines are important parts of a keg system. The tap is the device that dispenses the beer, and the lines are the tubes that transport the beer from the keg to the tap. It is important to keep the lines clean to prevent bacteria from growing, which can affect the taste of the beer.

Flavors and quality

The flavor and quality of beer can be affected by several factors when stored in a keg. Carbonation is important for the taste of the beer, and it can be affected by the pressure inside the keg. Oxygen can also affect the taste of the beer, as exposure to oxygen can cause the beer to become stale.

When storing beer in a keg, it is important to consider the type of beer, the cleanliness of the system, the lines and tap, and the factors that can affect the flavor and quality of the beer in given keg. By taking these factors into consideration, beer enthusiasts can enjoy a high-quality, flavorful beverage straight from the keg.

How to Dispose Appropriately of a Beer Keg

Once you're finished using a particular type of container (whether it was made from metal or plastic), proper disposal should be done accordingly so others can make use of it once more!

If opting out of recycling make sure you are following the local rules set by authorities regarding such actions; otherwise opt out directly by handing over your old containers at an authorized recycling center near you (make sure they accept both plastic AND metallic containers just in case!)

On the other hand – if reusing the same container then proper hygiene must be taken into account since unwanted substances may still linger within even after cleaning thoroughly!

What the Difference Between a Keg and a Cask

Casks have been used for hundreds of years and are usually used to hold non-pressurised, or 'flat', drinks.

Conventionally, cask beer is added to the container 'live' and goes through a second fermentation in the cask itself as the yeast matures. This type of product usually needs approximately 24 hours to 'condition' once opened, and because it is fresh, needs to be used within around three days.

Cask beers are served without the use of added gas as the carbonation is a natural by-product of the fermenting process. They are also usually intended to be consumed at a higher temperature than products from kegs, at around 11-13 degrees Celsius.

Other casks can also hold whisky, brandy, wine and port. However, these are generally wooden, and are normally a different size from beer casks.

At Close Brothers, the majority of casks we have available for hire are 464mm or 484mm 9 gallons.

In comparison, kegs have been around since the 1960s, with the containers introduced to provide longer shelf life and more consistent quality of dispense. Generally, kegs hold beer that has finished fermenting in the brewery and is completely ready to drink.

Kegs are frequently used to hold pressurised drinks, such as fizzy lager. These beers have nearly always been filtered and pasteurised to destroy leftover yeast and preserve shelf life. They are kept under pressure in an air tight container so there is less oxygen contact and the product can last a lot longer. The beverage can normally be served as soon as the container is opened.

Keg beer is typically served cold, between three and eight degrees Celsius, and requires food grade CO2, usually provided by your local pub, to carbonate the liquid. Any draught beer you order is likely being pumped up from a keg, using gas and electric pumps for momentum.

Kegs can also be used to hold soft drinks, wine, cocktails and even coffee.

At Close Brothers, the majority of kegs we offer for hire are 30 or 50 litres (52 and ¾ pints and 88 pints respectively) and can be fitted with various extractors.

Beer Keg Sizes and Types

These different types of kegs each have different characteristics, but if you know what you're getting into, it will help you make an informed decision about what kind of kegerator you need to maximize your draft beer enjoyment. By familiarizing yourself with the various types of kegs, you can select the one that best:

Cornelius keg

Alternate Names: Corny Keg, Homebrew Keg, Soda Keg

The tall, cylindrical Cornelius Keg (or Corny Keg) was originally developed (and still used) to store, distribute, and dispense soda like Pepsi or Coke.

However, with a five-gallon capacity (the size of a typical homebrew batch) and a design that's easy to fill, clean, and maintain, Corny Kegs have become very popular with homebrewers who want to skip the process of bottling beer and enjoy their brew on draft.

Most Cornelius Kegs utilize a ball-lock style connection, but some older models still feature a pin-lock style.

Cornelius Keg holds 53 12oz cans / bottles or 40 pints

Pints (16 oz) of beer per keg: Approx. 40

Cans / Bottles (12oz) per keg: Approx. 53

Capacity: 5 gallons / 18 liters / 640 ounces

Dimensions: 23" x 9"

Sixth Barrel Keg Size

Sixth barrel keg

Alternate Names: Sixtel, 1/6 Barrel, 1/6 BBL

A standard Sixth Barrel Keg (⅙ Barrel) is very similar in size, shape, and capacity to a Cornelius Keg but just a little bit bigger (5.16 gallon capacity vs. 5.0 in a Corny Keg). The main difference is that this style doesn't utilize a ball or pin-lock connection system but a traditional keg valve that requires a keg coupler for dispensing.

⅙ Barrels (or sixtels, as they're often called) have become increasingly popular because many craft brewers offer their small-batch experiments only in kegs of this size. Furthermore, many beer-minded restaurateurs that want to offer their customers a wide variety will opt for Sixth Barrel Kegs because they take up less space than their bigger brothers.

If you opt for a dual-tap kegerator in your home, you'll have plenty of options to serve on tap because you can fit two of these in one standard kegerator cabinet.

Sixth Barrel Keg holds 55 12oz cans / bottles or 41 pints

Pints of beer per keg: Approx. 41

Cans / Bottles (12oz) per keg: Approx. 55

Capacity: 5.16 gallons / 20 liters / 661 ounces

Dimensions: 23⅜" x 9¼"

Quarter Barrel Keg Size

Quarter barrel keg

Alternate Names: Pony Keg, Stubby Quarter, 1/4 BBL

The Quarter Barrel Keg (AKA Pony Keg or Stubby Quarter) looks like the standard beer keg you're used to from keg parties but much shorter (hence the "stubby" description). It's 7.75 gallons and perfect for small parties.

Quarter Barrel Keg holds 82 12oz cans / bottles or 62 pints

Pints of beer per keg: Approx. 62

Cans / Bottles (12oz) per keg: Approx. 82

Capacity: 7.75 gallons / 30 liters / 992 ounces

Dimensions: 13⅞" x 16⅛"

Slim quarter keg

Alternate Names: Tall Quarter, Slim 1/4 BBL

This tall, slender keg holds the exact same amount as its stubbier relative, the Quarter Barrel Keg. Much like a ⅙ Barrel, the dimensions of this keg make it a popular choice for people with dual-tap kegerators, but it holds 7.75 gallons, making it more than two gallons larger than a sixtel.

Slim Quarter Keg holds 82 12oz cans / bottles or 62 pints

Pints of beer per keg: Approx. 62

Cans / Bottles (12oz) per keg: Approx. 82

Capacity: 7.75 gallons / 30 liters / 992 ounces

Dimensions: 23⅜" x 11⅛"

Preventing leaks and maintaining pressure

To ensure the longevity of your keg, it is crucial to prevent leaks and maintain pressure. The first step in preventing leaks is to check for an airtight seal between the keg and the keg coupler. This seal must be tight to prevent any leaks. If there is a leak, it could be due to a faulty washer or keg coupler. It is essential to replace any damaged washers or keg couplers immediately to prevent beer wastage.

Maintaining pressure is critical to the flow of beer from the keg. To maintain pressure, check the carbon dioxide (CO2) tank regularly. If the pressure is too low, the beer will not flow through d system correctly, and if it is too high, it can cause the beer to foam excessively. It is recommended to keep the pressure between 12-14 psi for most kegs.

Cleaning and care

Keeping your keg clean is essential to prevent any build-up of bacteria or unwanted flavors. Regularly cleaning and sanitizing your keg, along with its components, will ensure that your beer tastes fresh and delicious. It is recommended to clean your keg after every use.

Troubleshooting

If you encounter any issues with your keg, such as a slow flow of beer or excessive foam, there are a few things you can check. First, ensure that the keg is properly pressurized and that the CO2 tank is not empty. If the pressure is correct, check the beer faucet, handle, and the keg coupler list for any damage or blockages. Check the spears sometimes these can become loose with keg couplers and if they do ask your distributor for another keg.

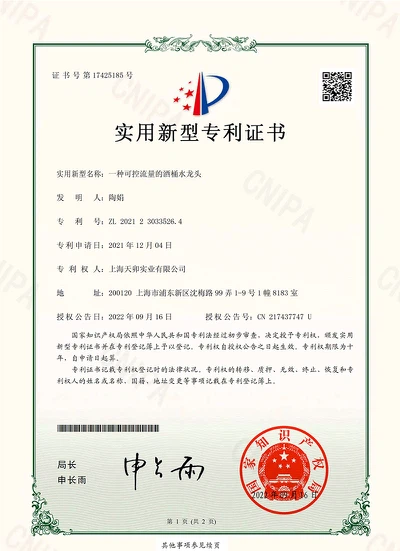

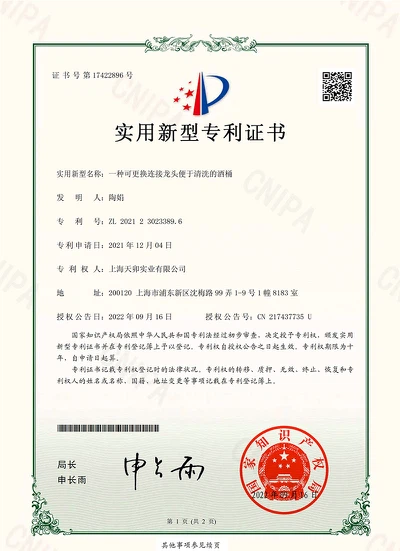

Certification

Pera Industry Co.,Ltd has been certified by ISO 9001 International Quality Management System and CCC(China Quality Certification Center). The whole process of production, management, and after-sales service is organized by the company. The quality of our products is in leading leval both at home and abroad, which is stable and reliable.

FAQ

Q: What is a beer keg?

Q: How do you store beer in a keg?

Q: What sizes do beer kegs come in?

Q: How long does beer last in a keg?

Q: How do you tap a beer keg?

Q: Are beer kegs reusable?

Q: How much beer can a keg hold?

Q: Can beer kegs be pressurized with different gases?

Q: How do you transport a beer keg?

Q: What are the safety precautions associated with beer kegs?

Q: How do you clean a beer keg?

Q: How do I know when a beer keg is empty?

Q: Can beer kegs be recycled?

Q: How do you know when a beer keg is empty?

Q: How do I troubleshoot common issues with a beer keg system?

Q: How are beer kegs filled?

Q: Can beer kegs be customized?

Q: What are the environmental impacts of beer kegs?

Q: How do you troubleshoot common issues with beer kegs?

Q: What innovations have been made in beer keg technology?

Hot Tags: beer keg, China beer keg manufacturers, suppliers, factory, single tap beer dispenser, spotted cow keg, 50l keg, 50l keg, 5 litre universal kegs, 5 gallon beer keg

No Information