Beer Regulator

A primary CO2 regulator for beer keg is essentially a small piece of equipment with one or two gauges, a valve, and two connecting points. As suggested by the name, this CO2 pressure regulator helps you to control the gas tank pressure within the workable draft beer limits (usually 10-15 PSI).The contents of CO2 & nitrogen gas tanks are under extremely high pressure. The main function of any regulator is to lower that pressure to a safer, more usable level before the gas reaches the keg. The regulator is also responsible for maintaining the optimal carbonation level of the beer being dispensed.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

What is Beer Regulator

A primary CO2 regulator for beer keg is essentially a small piece of equipment with one or two gauges, a valve, and two connecting points. As suggested by the name, this CO2 pressure regulator helps you to control the gas tank pressure within the workable draft beer limits (usually 10-15 PSI).The contents of CO2 & nitrogen gas tanks are under extremely high pressure. The main function of any regulator is to lower that pressure to a safer, more usable level before the gas reaches the keg. The regulator is also responsible for maintaining the optimal carbonation level of the beer being dispensed.

Advantages of Beer Regulator

Controlled carbonation

With a regulator, you can precisely adjust the carbonation levels in your beer, allowing for customization based on beer style or personal preference. This control is crucial for achieving the right balance of bubbles and flavor in each pour.

Extended shelf life

By maintaining optimal pressure, a beer regulator helps prolong the shelf life of the beer in the keg. Consistent pressure prevents oxidation and contamination, keeping the beer fresh and flavorful for a longer period.

Efficient dispensing

A regulator enables efficient dispensing of beer by controlling the rate of flow from the keg to the faucet. This efficiency reduces waste and ensures that every pour is smooth and consistent, enhancing customer satisfaction.

Versatility

Beer regulators are versatile tools that can be used with various types of draft systems, including kegerators, jockey boxes, and commercial draft setups. They accommodate different keg sizes and beer styles, making them suitable for both homebrewers and commercial establishments.

Why Choose US

One-stop solution

With rich experience and one-to-one service,we can help you choose products and answer technical questions.

01

Customization services

They provide customization services to meet specific customer requirements, ensuring that clients receive products that exactly fit their needs.

02

Innovation

We are dedicated to improving our systems continually, ensuring that the technology we offer is always cutting edge.

03

24h online service

We try and respond to all concerns within 24 hours and our teams are always at your disposal in case of any emergencies.

04

Understanding Beer Regulators

A beer regulator is a device used to control the pressure of the gas (usually CO2 or nitrogen) that is used in the carbonation and dispensation of beer. The regulator ensures that the gas is delivered at a consistent and appropriate pressure, which is crucial for maintaining the carbonation level and the overall quality of the beer.

Pro tip

Regulators can only ADD pressure. They cannot remove pressure from a keg by turning down the regulator. To remove pressure inside of a keg, you must pull the PRV (pressure relief valve) on the beer coupler (which will lower the PSI inside the keg and lower the regulator gauge).

Primary regulators

Primary regulators are directly connected to the CO2 or nitrogen tank. Their primary function is to reduce the high pressure of the gas in the tank (which can be upwards of 800-900 psi for CO2) to a more manageable level (usually between 10-30 psi for serving beer). This initial pressure reduction is crucial because it makes the gas flow more controllable and safe for use in beer carbonation and dispensation.

Primary regulators typically feature one or two gauges. One gauge displays the pressure of the gas being released from the tank (PSI), and the other shows the remaining pressure in the tank. Some primary regulators are equipped with a pressure relief valve (PRV), which is a safety feature that prevents the regulator and the keg from becoming over-pressurized.

Secondary regulators

Secondary regulators are used when there is a need to control the pressure of the gas to multiple kegs at different pressures. They are connected downstream of the primary regulator and allow for the pressure to be individually adjusted for each keg. This is particularly useful in setups where different types of beer are being served, as different beers often require different carbonation levels.

Unlike primary regulators, secondary regulators do not connect directly to the gas tank. They usually come into play after the primary regulator has already reduced the tank's pressure to a safer, more manageable level.

Proper Regulation of Gas Pressure Is Critical in Brewing and Dispensing Beer

Carbonation control

The level of carbonation in beer affects its taste, mouthfeel, and overall presentation. Different styles of beer require different levels of carbonation. For example, stouts generally have lower carbonation than lagers. Regulators help maintain the right carbonation level for each style.

Consistent quality

Inconsistent gas pressure can lead to over or under-carbonated beer, affecting its quality. Regulators ensure that the beer maintains its intended flavor and texture from the first pour to the last.

Safety

Handling pressurized gases can be dangerous. Regulators help mitigate this risk by controlling the pressure of the gas, thereby preventing accidents like keg explosions or gas leaks.

Choosing the Right Regulator

When selecting a beer regulator, several factors should be considered:

Type of gas: CO2 is commonly used for most beers, but nitrogen is sometimes used for certain stouts and ales. The type of gas will dictate the kind of regulator needed, as CO2 and nitrogen tanks have different fittings.

Number of kegs: The number of kegs being served simultaneously will determine whether a secondary regulator is necessary. The more kegs you have, the more control you will want at each individual keg, so secondary regulators become necessary. When only dispensing one-two kegs, you can get away with only using the primary regulator.

Pressure requirements: Different beers require different serving pressures, which should be considered when setting up your system. When dispensing multiple kegs, secondary regulators are the only way to precisely control the pressure at each keg.

Quality and durability: Given the crucial role of regulators in the brewing process, choosing a high-quality and durable regulator is advisable.

Low pressure gauge: Measures the pressure of the gas going into your keg.

High pressure gauge: Measures the amount of gas remaining in the tank.

Shut off valve: Opens and closes the flow of gas from the tank to the regulator and keg. Flow is open when the lever is parallel to the gas line, and closed when perpendicular to the line.

Pressure adjustment: Sets the level of pressure going to the keg. This may be adjusted by turning a screw or knob depending on the model of your regulator.

Outlet fitting: Connects air line from keg coupler to the regulator.

CO2 inlet: Connects regulator to gas tank. Use an air tank wrench to tighten or loosen the inlet nut.

Pressure release valve: Pull to release gas from the system

Principle and Structure of Beer Regulator

1. The body of carbon dioxide pressure reducer is made of brass < HPb59-1 >. The structure of the two-stage pressure reducing system is basically similar. It is composed of valve ejector rod, pressure regulating spring, elastic membrane device, pressure reducing valve and other parts. The first stage pressure reducing system is mainly used to automatically reduce the high-pressure gas to the medium pressure gas, to a pressure of 2MPa, and then send it to the second stage pressure reducing system. In the secondary pressure reducing system, when the pressure adjusting screw is screwed, the pressure reducing valve is opened and closed to different degrees through the pressure adjusting spring, elastic membrane device and valve ejector rod, so as to adjust the pressure reducing degree of oxygen supplied by the first pressure reducing system or stop the gas supply.

2. The thread size at the inlet joint of the carbon dioxide pressure reducer is G5 / 8 ", the inner diameter of the joint is 5. 5mm, the inner diameter of the outlet joint is 6mm, and the maximum flow rate is 80m3 / h. The pressure reducer body is also equipped with a high-pressure oxygen meter and a low-pressure oxygen meter, which respectively indicate the pressure in the high-pressure gas chamber (i.e. the oxygen cylinder) and the low-pressure gas chamber (i.e. the working pressure). The range of the high-pressure oxygen meter is - 25MPa. The range of the low-pressure oxygen meter is 0-v 4MPa o When qd-1 pressure reducer is used, when the adjusting screw is screwed clockwise, the pressure reducing valve can be opened, and the high-pressure oxygen will flow into the low-pressure chamber from the gap. The pressure is reduced due to the volume expansion of oxygen in the low-pressure chamber, that is, the decompression effect.

3. The thread size of the carbon dioxide pressure reducer inlet connector nut is G5 / 8 ", the inner diameter of the connector is 7mm, and the inner diameter of the outlet connector can be 5mm or 9mm according to different needs. The range of the high-pressure oxygen meter installed on the body is 0-25mpa, and the range of the low-pressure oxygen meter is 0-4mpa.

Types of Draft Beer Regulators

CO2 regulator

A primary CO2 regulator hooks up to your CO2 tank. In simple draft configurations, the air line then runs from the regulator to the keg coupler. If you are dispensing multiple kegs from one tank of gas, the airline might pass through a gas blender or secondary regulator before reaching the coupler.

Nitrogen regulator

If you want to dispense Guinness or any other nitro beer, you'll need a primary Nitrogen regulator. Like a primary CO2 regulator, it connects directly to the gas tank or cylinder to moderate its pressure. Unlike a CO2 regulator, it attaches to the tank by way of a female stem piece. A CO2 regulator will not properly attach to a Nitrogen tank. If you want to dispense a nitro beer without investing in a Nitrogen regulator, you can purchase a CO2 to nitrogen adapter piece instead.

Whether you are talking Nitrogen or CO2, primary regulators come in single-gauge and double-gauge models. Single-gauge regulators only have a low-pressure gauge, which measures from 0 to 60 PSI the output pressure of the gas being dispensed into the keg. Double-gauge regulators (shown above) have both a low-pressure gauge and a high pressure gauge, which measures from 0 to 3000 PSI the amount of CO2 or Nitrogen left in the tank. A high-pressure gauge is extremely helpful but not essential to draft beer dispensing.

Secondary regulator

If you are dispensing two or more kegs from a single gas source, a secondary beer regulator may be required. That's because different beers often call for different dispensing pressures to maintain the carbonation level prescribed by the brewer. Failure to adhere to the brewer's recommendation is to risk changing the appearance, mouthfeel, and taste of a beer.

Distribution bar

To dispense multiple kegs all at the same pressure, you'll need a distribution bar, which is basically a large splitter. The primary regulator determines the pressure of gas flowing through a distributor. A distribution bar does not allow you to adjust the pressure for each keg.

What You Need to Know About Draft Beer Regulators

Dispensing a consistently carbonated head on your beers means keeping proper, substantial pressure flowing through your air hoses. Without controlled pressure the gas released from your tank will be entirely too strong, making it difficult to dispense beer. This is where the regulator comes in. The basic primary CO2 regulator can have a single gauge that simply measures the dispensing pressure, or a double gauge regulator that will let you know how much pressure is going to the keg and how much gas is left in the tank.

Tapping Guinness requires Nitrogen and a different regulator. You can either use a Nitrogen Regulator or a CO2 regulator with a Nitrogen Tank Adapter.

To tap multiple kegs, a distribution bar is required like the CO2 Distribution Manifold, which can hold up to nine outlets. This bar will distribute pressure evenly throughout the various beers. If each keg requires a different pressure, you'll simply need a secondary regulator. Equipped with individual pressure gauges, we offer secondary regulators that can run up to five kegs off one gas tank.

To keep pressure maintained at the correct level, you must make sure you find the right PSI (pounds per sq. in.). For CO2 tanks, the pressure should rest between 10-15 PSI and for Nitrogen tanks, it should be around 30-40 PSI. Also, don't forget to keep your air tank upright. Otherwise, you could damage your regulator and temporarily halt your draft system.

Features of Beer Regulator

Never have too much or too little foam on your beers Serve the beer with the perfect top – every time.

No more manual adjusting! The DraftMore automatically adjusts the CO2 pressure in the keg according to the beer temperature.

The CO2 content in the beer remains the same as when the beer was delivered from the brewery.

DraftMore will automatically shut off the supply of CO2, when beer is not poured, in contrast to a normal installation, that means no CO2 will be let into the beer, over night and destroy(overcarbonate) your beer.

No more flat or foamy beer.

DraftMore replaces a standard secondary C02 regulator.

It's easy to install one on each tap – find installations video in right margin.

Optimize dispensing and stop pulling beer down the drain.

Beer consumption will be higher – Bar staff will be able to work faster and not wait for the perfect beer to stabilize before they can tap next beer.

Tips for Optimal CO2 Regulation

To make the most of your primary regulator and achieve optimal CO2 regulation, here are a few tips to keep in mind:

- Regularly check and calibrate your regulator to ensure accurate pressure readings.

- Use a pressure relief valve to prevent over-pressurization and potential accidents.

- Consider investing in a dual-gauge regulator, which allows you to monitor both the tank pressure and output pressure simultaneously.

- Keep spare CO2 tanks on hand to avoid running out during critical brewing stages.

- Consult the manufacturer's instructions and recommendations for your specific primary regulator model.

How to Connect a Secondary C02 Regulator

When you connect a secondary regulator down stream from your sourced C02. Usually, it's going to happen somewhere close to the keg it's supplying C02 to.

Back to connecting a secondary regulator.

In a kegerator the connection will be right above the kegs. In a walk-in cooler whether it's a direct-draw or remote system, the regulator should be close to the keg it's supplying as well.

Take the regulator and use ½"- ¾" sheet metal screws to attach the reg to the cooler or kegerator wall. I'll sometimes use ¾" stainless self-tapper screws with a 5/16 nut drive. These screws have worked well for me over the years.

Next, take the supply C02 and connect it with high pressure braided ¼" air line and attach an otiker clamp (13.3) or a hose clamp to secure that connection. I like to use ¼" I.D. Braided line to distinguish my higher pressure C02 coming into the draft system. You can use the red- airline if you like, but don't exceed the max pressure rating on the airline. I like to use the braided line because I'll set my primary reg anywhere from 80-100 PSI and I need a high pressure tubing. From there, I will regulate my exact pressure with the secondary regulators to the kegs.

After that connection, I'll take the red-airline, connect the hose fitting that supplies c02 from the regulator with a 16.2 or 15.7 otiker. Then connect the other end to a beer coupler or tavern head.

How to Adjust the Regulator

Adjusting the regulator is very simple to do. It's very similar to adjusting a primary regulator. Depending on the type of regulator will determine how you can adjust. Some will have pull out knobs on the front like Taprite, and others will have adjustment screws. For the regulators with adjustment screws, you will need to use a flat head screw driver to adust the pressure.

When adjusting pressure make sure that the c02 main pressure is on coming from the primary regulator or source. Shut off the hose valve or make sure the secondary is in the off position. Pop out the knob and adjust accordingly.

If the regulator has an adjustment screw, ( Micro Matic) adjust the pressure by turning the screw clockwise to adjust the pressure.

Set the secondary Regulator anywhere from 10-12 PSI. Again, this depends on the beer cooler temperature, the type of beer you're pouring, restriction values and altitude.

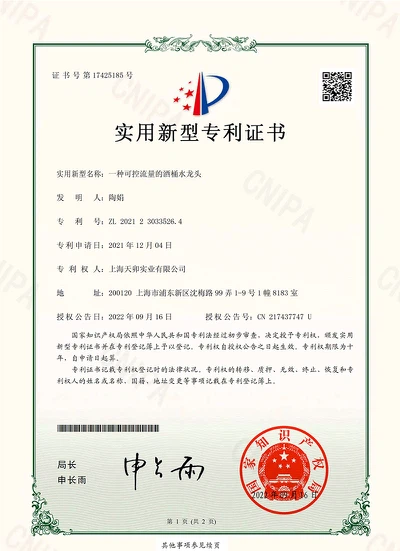

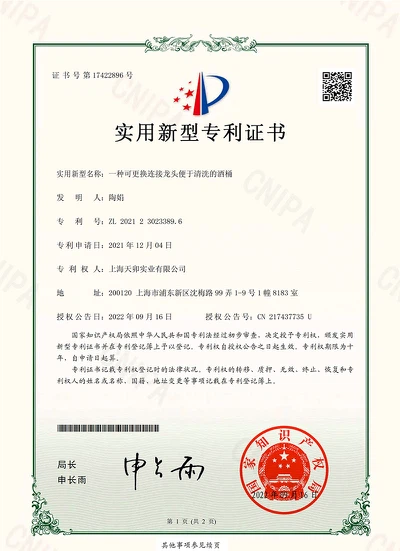

Certification

Pera Industry Co.,Ltd has been certified by ISO 9001 International Quality Management System and CCC(China Quality Certification Center). The whole process of production, management, and after-sales service is organized by the company. The quality of our products is in leading leval both at home and abroad, which is stable and reliable.

FAQ

Q: What is a beer regulator?

Q: How does a beer regulator work?

Q: Why is pressure regulation important in draft beer systems?

Q: What are the main components of a beer regulator?

Q: Which types of regulators are there for draft beer systems?

Q: Can I use a regulator with different kinds of beer?

Q: How do I adjust the pressure on a beer regulator?

Q: How often should I check my beer regulator?

Q: Can a beer regulator be used with nitrogen gas?

Q: How do I clean a beer regulator?

Q: What is the difference between a high-flow and a standard beer regulator?

Q: Can I use a beer regulator with a corny keg?

Q: What is the lifesspan of a beer regulator?

Q: How do I store a beer regulator when not in use?

Q: Can I repair a broken beer regulator?

Q: What causes foaming in a draft beer system despite using a regulator?

Q: Can I use the same beer regulator for different size kegs?

Q: Do I need a separate regulator for each keg?

Q: How do I know if my beer regulator is leaking?

Q: What is the ideal pressure for a draft beer regulator?

Hot Tags: beer regulator, China beer regulator manufacturers, suppliers, factory, g system keg coupler, keg kits, beer tap regulator pressure, beer infusion tower, kegerator c02, mini co2 beer regulator

No Information